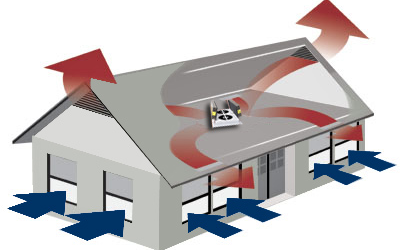

IGU, also referred to as Insulated Glass Unit, is the most important part of a window. It is responsible for providing the large surface area of glass exposed to the exterior and interior simultaneously with an insulating barrier. The IGU is filled with inert gases pumped inside double and triple-paned window assemblies (the complete Insulated Glass Unit or IGU) to improve their thermal efficiency. These viscous, slow-moving gases (typically, argon and krypton) allow for less convection than would ordinary air, minimizing convective currents within the window and reducing the transfer of heat across the window.

Homeowners may be able to tell if their home’s windows are gas-filled by checking the specifications on the original work order or the window tag, which is typically found along the bottom inside track of the window, as well as observing a small hole along the spacer (explained below) where the inert gas is pumped in to the unit while air is simultaneously vacuumed out.

Argon and krypton are the gas fills used most often by window manufacturers to displace the air between the panels in windows. Argon, which comprises slightly less than 1% of the Earth’s atmosphere, is non-toxic, inert, clear and odorless. Its thermal conductivity is roughly 67% that of air and it’s inexpensive, making it an attractive gas fill. Krypton shares many qualities with its fellow noble gas argon, except that it’s an even better insulator, as well as more expensive to produce, though when cost and functionality are considered, argon is a more efficient thermal barrier per dollar spent, especially in the larger 1/2 inch to 7/8 inch spaces between the panes of glass.

Surrounding the insulating gasses is a spacer that separates the two, or sometimes three, panes of glass. The most efficient and effective way to separate the glass is with a rigid foam also know as Super Spacer.

Super Spacer is a rigid foam designed to expand and contract, but it will always maintain its structural integrity by returning to its original shape. This is very important because windows are constantly exposed to temperature changes, UV rays, barometric pressure changes and wind that will cause the glass to expand and contract. Other rigid spacers contain metal that does not allow for the natural expansion and contraction that must occur in the insulated glass unit to offset the effects of these pressures on the glass. If the IGU isn’t allowed to expand and contract the results are stress cracks and seal failures.

Completing the seal of the IGU is rubber butyl seal directly behind the Super Spacer. This thick bead of butyl provides yet another seal to insure the pressurized insulating gasses remain inside the IGU for many years.

IGUs provide an efficent and effective way to keep the elements out of your home. If you’re interested in learning more about IGUs and the other parts of vinyl replacement and new construction windows, Lindsay Windows has a great education page to help you out. Simonton windows also offers an education page for further reading. And as always if you have any questions you can contact us!

Recent Comments